WHY PRODUCE NITROGEN?

Nitrogen is a popular gas used in a variety of today’s industries. The atmospheric air that surrounds us contains approximately 78% nitrogen.

Due to N2 being inert and being a replacement for air where oxidation is unwanted or unsafe, this widely used gas can be found in the following industries:

- Oil and Gas

- Chemical Processing

- Food Industry (Packaging and Processing)

- Gas Injection Molding

- Metals Industry (Production and Fabrication)

- Beverage Industry (Alcohol and Non-Alcohol)

- Pharmaceuticals

- Rubbers

- Forestry

- Mining

- Many More…

Because CAE specializes in compressed air, it’s only natural that we would also specialize in providing solutions for N2 as well. From a financial perspective, your business could potentially be spending more money than it needs to with its current Nitrogen provider. CAE will assist you in outlining the substantial savings you’ll see from generating your own N2 vs bulk N2 delivery.

No matter what your requirements are for purity, volume, or pressure, we can provide you a nitrogen solution that can be as simple as an “out of the box” N2 generator to a complete custom engineered turnkey containerized package. At CAE, there’s no job too big. We can accommodate purity requirements up to 99.999%, pressures up to 21,750 PSI, and endless volumetric flows by use of multiple systems.

HOW WE PRODUCE N2 GAS

A number of methods can be used in the production of N2 Gas. CAE provides our customers with two options depending on purity, volume, pressure, and budget. These two options are Osmosis Membrane Technology and Pressure Swing Adsorption (PSA) Technology.

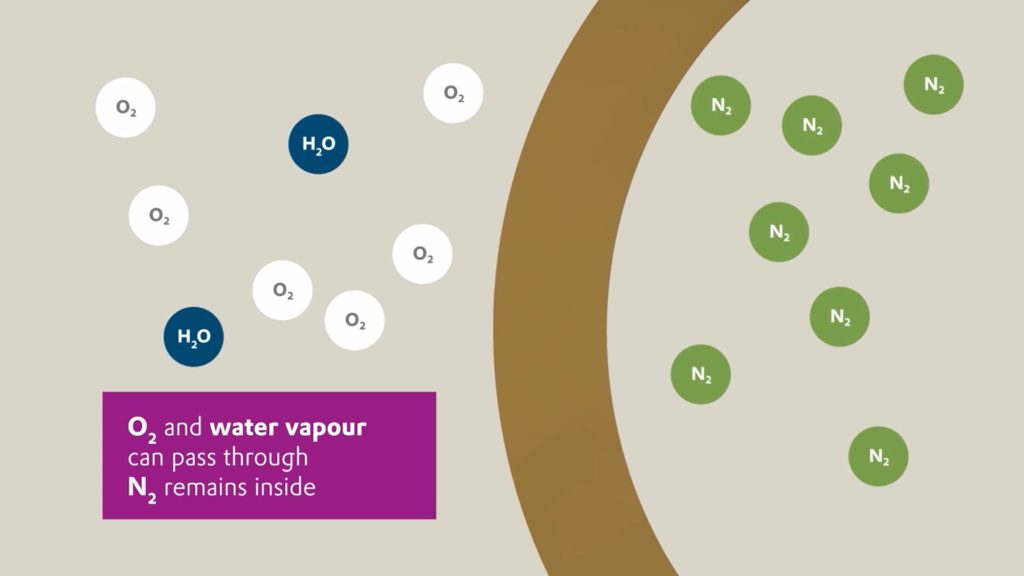

Membrane Technology is more simplistic than a PSA system as there are no moving parts to a membrane. Membranes are simply cylindrical cartridge style filters that contain many bundled polymer fibers. Compressed air enters the Membrane and the separation of air’s Oxygen and Nitrogen molecules is accomplished.

Pressure Swing Adsorption is more complex than using a Membrane system as there are moving parts and several individual components that all work together to complete the separation process. Rather than the polymer fibers found in a membrane system, PSA’s use an absorption component called Carbon Molecular Sieve (CMS). If you are familiar with Twin Tower Desiccant Compressed Air Dryers, PSA Nitrogen Systems are very similar in design and functionality. PSA Systems have an advantage to conventional membrane systems where higher purities of N2 can be achieved.

Trailer Mounted Nitrogen Unit

This particular package that we customized for an Oil and Gas client here in Canada, and it truly emphasizes our mobile design capabilities. What you see here is a completely mobile Nitrogen Generation Package ready to be picked up and towed to site. It even comes complete with an onboard power generator for remote areas where electricity from the grid is not available.

This package utilizes a Nitrogen Membrane system, where a total of three parallel membranes are used to generate the Nitrogen for the client’s intended use and requirements. You’ll also notice that this enclosed package is heated, vented and insulated to provide the Nitrogen Generation System ideal ambient operating conditions inside the enclosure.

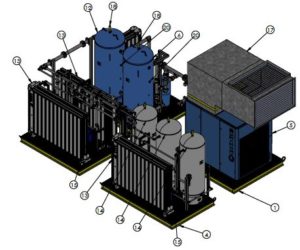

Skid-Mount Electric N2 Generation Package

Not only did our customer in this application (Coil Tubing purge) require Nitrogen, they required Nitrogen at High Pressures (2250 psig). This project was an excellent example of how we can combine our different capabilities for Nitrogen and High Pressure into one complete skid-mounted package.

This particular system uses a Pegasus Air Compressor from our Partners at Stallion Air Incorporated in the USA. Capable of up to 7,000 PSI (If needed), this unit has no problem generating Nitrogen at the pressure required by our customer. This package comes complete with Air and Nitrogen storage tanks which not only act as storage vessels but also act as pressure buffers to ensure the consistent flow of Air and Nitrogen are being delivered.

Containerized Membrane Nitrogen Package

This particular Nitrogen Package we built for a local company in the Energy sector, and we believe it shows our capabilities of combining our Skid Mounted design with our Containerized Packages. As you can see, this is a containerized enclosure mounted on a fabricated skid frame. This package was designed to have multiple tie-in connections on the outside when additional feed air is required.

This solution was designed as a “point of use” system where compressed feed air is supplied on the individual sites where this package would be transported to. You’ll notice that we have installed a “radiator” type heat exchanger and large filter to the outside of this package so that the compressed feed air from site can cool down and be cleaned prior to entering the Nitrogen Membranes onboard this package (thereby preserving their life and optimizing their efficiency). Lastly, take note of the amount of space we’ve provided in the design and build of this package – space required for serviceability down the road.

From a maintenance perspective, there’s an abundance of room for on-site Millwrights and other technical personnel to work comfortably.